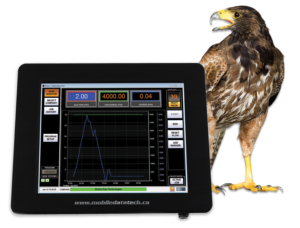

The mDRS is the all-in-one solution for in shop testing. Its bench top design makes it easy to use for most test facilities. The mDRS was featured in the February 2011 issue of the Oil & Gas Network magazine with a Trican friction reduction unit. With a touch screen interface the mDRS allows easy PDF report generation and email capabilities. With these features in mind, the mDRS is a must have for in shop data acquisition.

KEY FEATURES

TOUCH SCREEN

Industrial touch screen PC with simple, easy to use interface

ANALOG CHANNELS

Includes 4 analog channels

RELAY OUTPUT

Includes 1 relay output switch (rated at 10A)

REMOTE SUPPORT

Built in remote support (requires internet connection)

REAL TIME MONITORING

Real time monitoring or recording of analog (pressure, temperature, force, differential pressure, viscosity, etc.) or frequency (flow rate/total) signals

SAFETY SHUTDOWN

With use of a supplied relay it can provide automatic safety shutdown control

PDF REPORTS

PDF reports of all jobs saved on the hard drive, transferred to an in house server and easily transferred to a USB stick. Email capable (with an internet connection), printer capable (not supplied with base system).

SYSTEM SPECIFICATIONS

– 15” Industrial Panel PC (touch screen)

– Windows 7 Embedded OS

– 1.8GHz dual-core (Intel Atom D525) processor

– 80GB SSD, 3GB RAM

– IP65 front panel

– Two USB ports

– Ethernet and Wi-Fi (wireless 802.11 b/g/n)

– 4 M12 sensor electrical connectors

– Optional Relay Outputs

SYSTEM REQUIREMENTS

Power input

– 120 VAC

STORAGE | OPERATING LIMITS

Storage temperature

-40°C to 70°C (-40°F to 158°F)

Operating temperature

-10 °C to 50°C (14°F to 122°F)